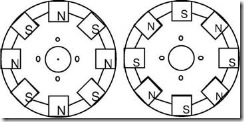

. THE TWO ROTORS ARE NOT THE SAME

Stainless Steel wire

When the PMG is turning, the magnets will try to fly off the rotors. There is a large centrifugal force pulling the magnet blocks to fly away. When we started building these PMGs, the magnet blocks were simply glued to the steel disks. When the PMGs turned fast, the magnets flew off, and the wind generators were destroyed.

Now we embed the magnets in a resin casting. Resin alone is not strong enough to hold the magnets. It should be reinforced. Wrap wire around the outside of the magnet rotors to hold the magnets in. Steel wire is strong enough, but steel would take the magnetism from the magnet blocks. We use stainless steel because it is not magnetic and it does not spoil the effect of the magnets. Stainless steel wire cable is used on fishing boats.

Before using any resin assemble the parts dry. Put the stainless steel rope around outside the magnets five times, and cut it off with a grinder or chisel. Tape it in several places so that it is in a coil, ready to drop into place later.

Rotor casting procedure

Before starting, check that everything is ready:

• the moulds are prepared with polish or release agent,

• the magnets and the magnet disks are clean and bright (no grease),

• 1 6 strips of CSM are ready to fit between the magnets

• the stainless steel wire is cut to length and taped

• the magnet positioning jig is ready

The amounts of resin mentioned in this procedure are enough for two magnet rotors.

Комментариев нет:

Отправить комментарий